Early 80s

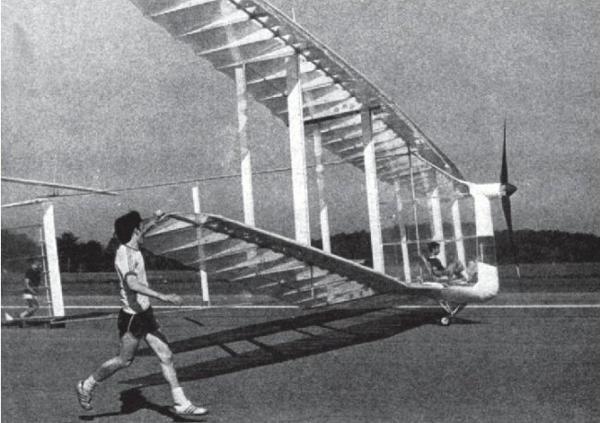

CHRYSALIS

The project started when some MIT students tried to fly BURD II (see above) with the assistance of model aircraft engines in November 1978. This resulted in a smashed BURD, but the experience sparked new ideas, and Harold Youngren, Bob Parks, John Langford, and Hyong Bang decided in early December 1978 to design and build a new machine.

This had to be flying by May 1979 when these final-year students were due to graduate. Other objectives were, a maximum 75 ft (22.9 m) wingspan so as to fit the hangar, and a plane able to be flown by anyone and easy to repair.

These objectives led logically to the choice of a wire-braced biplane. The usual theoretical optimisation process was performed to finalise dimensions, and to decide the control system an 1/8th scale flying-scale-model was made. In its final control configuration, with developed control techniques, it was possible to fly this radio-controlled model in turns as tight as 2 1/2 spans in radius. As a result of these model tests it was decided to adopt conventional tail controls and wing-warping for the full-size plane. A test-section of wing was made and resulted in several important changes in design and constructional details. The team developed a method of anchoring the bracing wire 36% more efficient than that used on the Gossamer Condor. The Czerwinski method of joining the aluminium tubes was used.

The project was officially recognised by MIT and funded. More students, including Mark Drela, joined the team to help with construction. Professor E. Eugene Larrabee's minimum induced loss propeller design process was used.

In March 1979, Larrabee met Paul MacCready who suspected that the propeller on the Gossamer Albatross could use some improvement. Guppy Youngren designed a propeller for Albatross using Larrabee's method and sent the plans to MacCready.

A few weeks later MacCready was able to help the Chrysalis project by supplying the Mylar, an essential item which the team could not obtain elsewhere.

Anyone involved in a project today, can often benefit by co-operating with other groups, and the two problems mentioned here can be more easily solved. Other enthusiasts can put you in touch with suppliers of Mylar (Melinex in Europe), or other materials, and with a propeller design program.

Construction of Chrysalis took 3 times the originally estimated number of person-hours, but the plane was built in 91 days, and when nearly complete, proceeded for 72 hours round the clock.

Chrysalis made two flights on the 5th June 1979, the first day it had left the hangar. Within 3 weeks it was making 120 degree turns. One major modification was the addition of a fairing at the aft of the pod to lower wing junction. See interference drag in SUMPAC above.

Chrysalis provided recreational flying for 44 pilots, some inexperienced, and one very experienced: Bryan Allen, just back from flying to France. He found Chrysalis to require less power than Condor for cruise although more for climb and particularly that it was a more stable aeroplane.

Chrysalis in 1979

MiLan

There were no new aircraft at Nihon University from March 1978 to December 1981, when the MiLan'81 first flew. This was a totally new configuration, an almost rectangular high wing to which were attached twin tail booms with the propeller between them just behind the pod. A large number of bracing wires from the top of a kingpost to the wing and from the wing to near the small wheel. The pilot was upright. This aircraft flew 645 yards. A similar plane, the MiLan'82, flew on the 16th Oct 1982. Cruising speed was 12 mph (5.4 m/s). The twin booms were far enough apart for a 14 ft (4.3m) propeller.(Continue with Swift)

PHOENIX

Frederick To, an architect, made a film about HPF called "The Last Challenge" in 1974. He started building Solar One with the help and advice of David Williams (see SUMPAC) in 1977. In 1978, Solar One became the world's first solar-powered-aircraft. In this same year he began considering inflatable HPAs, seeing the advantage of portability and less vulnerability. He acquired the Reluctant Phoenix, and followed several of Perkins' techniques, including the elevon hinge system, in the design of his own inflatable, the Phoenix.

Wanting to use Melinex, rather than traditional balloon fabric, To first had to develop a system for bonding this material (F.To Aerospace June 1985), enabling the "T" joints to be made. Built like a flying airbed, there are a quarter of a mile (400 metres) of such joints between the skin and the vertical webs. F.To chose a rectangular configuration, to maintain constant skin tension and Reynolds number along the span, a flying wing configuration, because otherwise the inherent simplicity of rigging and transportation would be lost, winglets to enhance ground effect, and a span of 100 ft (30.5 m) with a 16.7 ft (5.1 m) chord. He estimated a weight of 85 lb (38.5 Kg) and power requirement of 1/3rd HP. He realised that cable operated controls would be out of the question because he anticipated the wing stretching 9 inches (230 mm) when inflated. Operation was by model aircraft servos, 4 servos to each elevon.

Work on construction of this largest ever HPA wing took place in a suburban house in a room 12 ft by 26 ft. (3.7 m by 8 m)The workbench was just longer than the chord. The material was fed across spanwise as it was worked on.

Wind-tunnel tests at Imperial College, London showed that the winglets reduced induced drag by a quarter. They also showed that the profile drag would be ten times more than for a smooth shape of the same section, whereas To had assumed a factor of only 1.25 in his power-requirement estimate. The model's profile replicated the series of flats and curves to be expected on the inflated shape. By this time, construction of the actual wing was advanced. Frank Irving of Imperial College sugested a series of hoops, with the outer skin above them, and these were used on the plane. Performance indicated their effectiveness.

Eventually inflation could be done in 20 minutes and deflation 30, but the first few times it took much longer than this. Phoenix could be carried deflated on a car-roof-rack. Fred To said the most awkward thing to transport was the propeller. On 28th March 1982, it was planned that Ian Parker would make the first test-flight inside the 600 ft (180 m) warehouse where it had been rigged. However Ian Parker thought better of this, and took it outside and took off. The weight was 105 lb (48 Kg), but there was 200 lb (91 Kg) of air inside the wing which had to be accelerated during the take-off run. (How to tell the difference between weight and mass ? Try to do a take-off run in an inflatable HPA.) The pressure of this air was small enough that the density above atmospheric air was insignificant, but because of its enormous volume, the mass was nearly double that of the airframe. Control was adequate and flights were made by all group-members, but no great distances were covered. In May 1982, Barry Jacobson took over the Phoenix, intending to reduce its thickness to make it more manageable.

Phoenix flying in Docklands, London in 1982. RAeS collection

KREMER FIGURE-EIGHT COMPETITION ( continued )

A prize of £ 10,000 was still available in 1980 for this course. The first figure-eight had been flown by Bryan Allen in the Gossamer Condor, in the USA. The rules stated that an entrant for the competition must be from a different country. The competition was to close at the end of June 1984. Three aircraft raced to beat this date, and each other.

HVS

The HVS was designed by Hutter, Villinger and Schule. Franz Villinger had been responsible for the Mufli 48 years previously. Wolfgang Hutter had designed gliders and Wilhelm Schule had constructed airframes. With the experience of the designers, and with backing from industry a neat and sophisticated-looking plane resulted. However it would appear that this was another disappointing low-wing aeroplane. The longest distance flown being little more than that of the Mufli. Achievement of the HVS has been to operate in high winds; speeds greater than 21 mph (9.4 m/s) (the plane's cruising speed) have been quoted. (Aero Modeller, Aug 1983).

ADJUSTMENTS would have been difficult to make on the HVS. The "V" tail precludes adjustment of vertical or horizontal tail area; and the canopy fits pilots of only one height. On this plane, the pilot operated non-rotating pedals to drive an adjustable pitch propeller. The drive mechanism was complex, entailing cable runs to the pylon where there are chains to contra rotating flywheels on the prop-shaft. With a cantilever wing of 54 ft span and a carbon-fibre structure, the HVS first flew on 12th March 1983.

COMPETITIONS

The HVS was designed and built before the setting of the Kremer World Speed Competition, yet its cruise speed of 21 mph was just in the range to make it a contender had it been more successful.

PELARGOS 2

In 1980, Max Horlacher the head of a small company which worked with composites, hoped to build a plane which his son, then eleven, could fly and which could be entered for the Kremer figure eight competition. His first plane, Pelargos 1, did not take off, and although he blames this partly on the fact that his son had put on too much weight, he decided to call in assistance for his next design. Fritz Dubs, an aerodynamicist from Zurich who collaborated on the II pointed out that the aerofoil section must be changed to be suitable for the very low speed at which they intended to fly the new plane. The firm of Reichhold Chemie AG supported the project by supplying the synthetic materials used. It is noteworthy that the wing-ribs and other secondary structural items on this aircraft were made from carbon, compared with the more usual and cheaper foam sheet construction. Other unusual structural features were a rigid strut and a light rear-spar. This rear-spar, as well as stiffening the wing generally was also made to serve as a place on which to make the joint between the sheets of Mylar, the greatest available width being six feet, and the chord of the wing over eight feet. It might seem that the wing could have been covered by using the width spanwise, and forming the joints on ribs; but if "tensilised" Mylar was used then this would explain their procedure. Tensilised Mylar shrinks more in one direction than the other when warmed. If correctly oriented, it will provide a better approximation to the rib shape between the ribs.

The propeller was 12 feet in diameter, one of the largest used. For ease of construction, a rectangular shape was chosen for almost everything else. This aeroplane was one of the first to be easily transportable in sections. The constructors benefitted from Horlacher's business experience, and the lessons learned on the plane were, in turn, useful to the business, as well as an advertisement for them and for Reichhold. Once the Pelargos 2 was constructed, it was put on display at a trade show in March 1983, but did not make its first flight until seven months later, because of difficulties in finding a satisfactory transmission system. A Cardan type universal joint was one of the options considered for this.

On January 20th 1984 Horlacher wrote to the RAeS to enter for the Kremer figure eight competition. Max Horlacher knew that there was competition both from the HVS and from Rochelt's Musculair. He wrote "I do not grudge the German team its success up to now. Both the aeroplanes are distinctive. One could be curious which will be successful".

The Pelargos 2 first flew in December 1983. On a later flight it covered a distance of 1100 yards (1000 m). (See http://www.skytec-engineering.de/pelargos.htm).

MUSCULAIR I was built by Holger Rochelt and Gunter Rochelt, and designed by Gunter Rochelt, Ing. Ernst Schoberl and Dr.Ing. Heinz Eder. Gunter Rochelt had previously built a successful and radical solar-powered-aircraft. This human-powered-aeroplane was not built with the intention of winning a Kremer Prize. It was built with the intention of winning two Kremer Prizes. But it didn't. It won three of them! Although there are many difficulties in the design of an HPA, one of the ways in which it is easier than for most other classes of aeroplane is that one has generally needed to only consider a narrow speed range. But Ernst Schoberl in his optimisation process aimed to find a shape which would be suitable both for the figure-eight course and for the speed course (see next page), and it would be piloted by Holger Rochelt who was of only average athletic ability. As can be seen from the table, the wing area of 173 sq ft (16.5 m2) was one of the smallest used on an HPA, and contrasts with the 760 sq ft (70.6 m2) of the Condor, the only other plane to fly a figure eight. A conventional configuration was chosen, with the propeller behind the tail, the drive shaft being the length of the tail boom. This propeller had previously been used on the solar-powered-plane. Spar construction was by laying-up cloth onto a rectangular block of foam: firstly diagonal weave all round, then spanwise strips top and bottom. Ribs were foam sheet, and the wing was skinned at the nose area, then covered in Melinex. The torsional stiffness deriving from the box-spar and the Melinex covering was found to be insufficient and it was found necessary to involve the "C" shape nose skinning in the task of load-carrying. This was done by adding diagonally-braced carbon-fibre rovings and effectively changing the "C" to a "D", thus forming a closed box. The plane was built in three months and made its first flight, as yet without cockpit fairing, at the end of May 1984. Within two weeks, on 18th June 1984, Holger Rochelt made a figure-eight flight. One Kremer prize for the Rochelts, the second ever figure-eight in HPF.

Musculair I story continues later